We supply premium-grade check valves that surpass all industry standards in terms of quality, efficiency, design, and durability.

Menu

close

Menu

close

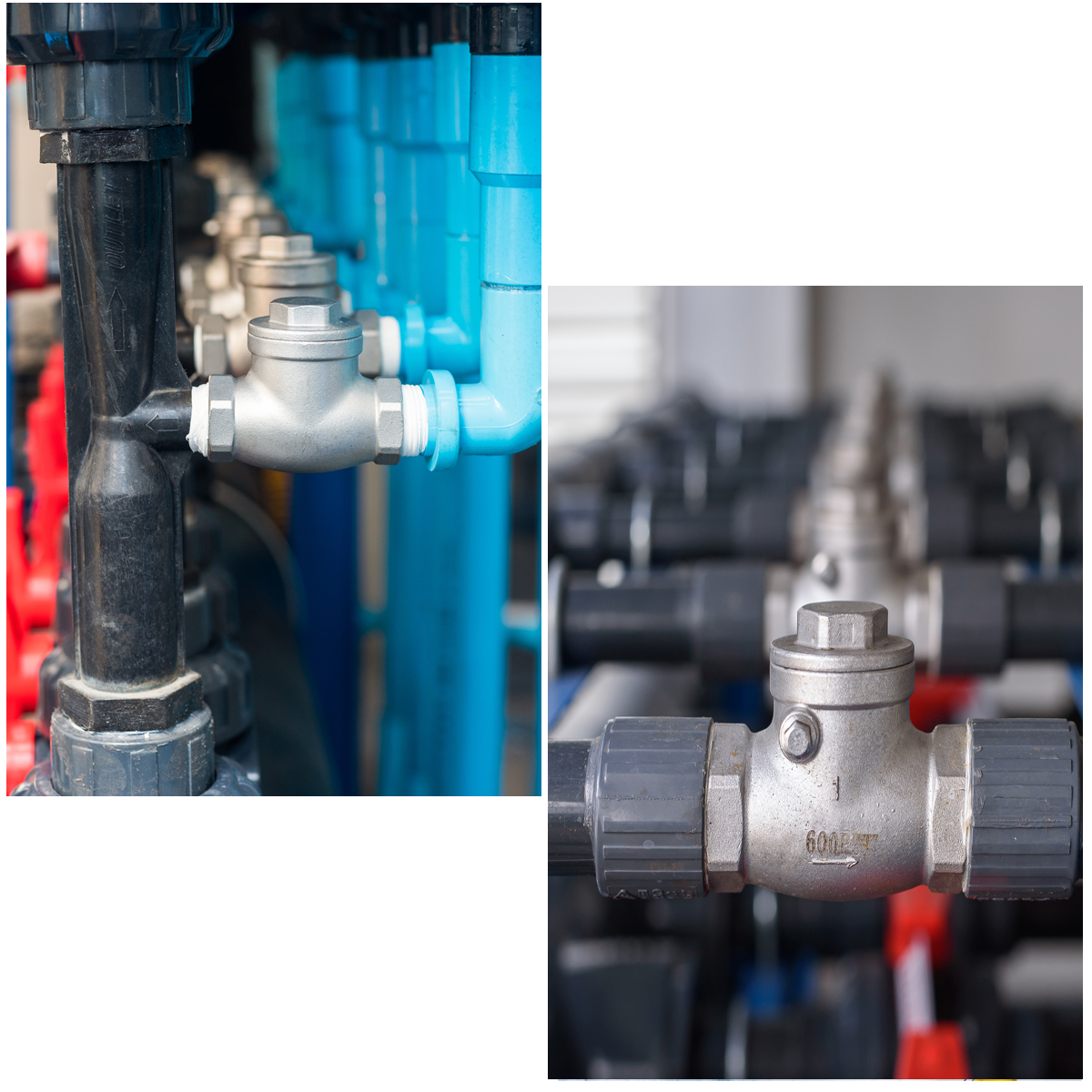

We supply premium-grade check valves that surpass all industry standards in terms of quality, efficiency, design, and durability.

The check valve is a universally prevalent device in any industrial scenario. As a directional control valve, the device’s primary purpose is to control the direction of the media flowing through the pipelines. Another remarkable characteristic is their unidirectional function. In other words, the valve allows the media to flow only in one direction, which is why they are called non-return valves.

A full-fledged check valve comprises multiple components like nuts, bolts, gaskets, body seats, cover plates, and a disc. The valve works when there is sufficient fluid pressure in the line, while gravity or back pressure keeps it tightly sealed.

Alter Valve is the best-known check valve supplier in Russia’s industrial realm, thanks to its advanced manufacturing and staunch quality processes. Our check valves are used in a myriad of simple and complex applications in all industrial processes.

We are the ideal partner for all your heavy-duty check valve requirements, serving as a trusted valve supplier in Russia.

To meet all of your industrial requirements, we offer a comprehensive range of solutions.

Manufactured with self-operating technology to eliminate the need for constant human intervention.

Diverse range of raw materials such as cast steel, carbon steel, stainless steel, and alloy steel procured from the best vendors across the globe.

Multiple check valve types to fit your industrial applications. We offer swing check valves, bolted cover valves, and double-flanged or butt weld end valves.

Effective protection against reverse flow contamination and equipment damage caused by media backflow.

Extensively used in chemical, oil and gas, petrochemical, power industries, and water treatment plants.

Employed in fire protection systems, shipping operations, wastewater treatment facilities, and rainwater harvesting systems.

Suitable for industrial applications with high pressure, extreme temperatures, corrosive media, and high vibration levels.

Serves a wide range of non-industrial purposes such as potable water distribution, drip irrigation, and heating systems.

You should look for:

Basically, a check valve can be divided into four individual parts:

Other components like springs, hinges, bolts, pins, and stems are added according to the purpose and design.

Check valves are robust devices built to endure variable pressure extremities and flow conditions during the industrial process. They do not require power to operate and can be used horizontally or vertically as per the application.