Ever thought about the role valves play in keeping our industries running smoothly? Valve suppliers call them the unsung heroes of the industrial world. They are devices designed to keep things flowing just right.

This article dives deep into the world of industrial valves, their types, usage, and some smart tips for picking them out. Whether It is oil, chemicals, or energy creation, we will see how these mighty tools shape different sectors. Ready to appreciate the strategic place valves hold in boosting both efficiency and safety in the industry?

Evolution of Industrial Valves in Various Industries

Let us journey back in time. Did you know valves have been managing fluid flow for over two thousand years, starting with Roman ingenuity? Valves gained popularity in the 19th and 20th centuries, but their demand peaked in the 1960s.

This surge led to the valve varieties we see today. The ball, check, and butterfly valves are all tailored to our modern needs. This valve history demonstrates how our pursuit for improvement has enabled the progression from simple to complex designs. Now, no matter your industry's demands, there is a valve engineered just for you.

Types of Industrial Valves and Their Mechanisms

Valves are key in guiding fluids like liquids, gases, or slurries. They are of two main types.

- Manual, which people operate.

- Automatic, which runs on motors or actuators.

This choice affects how much control and automation you have in your work. There are many designs and materials, each picked for specific tasks.

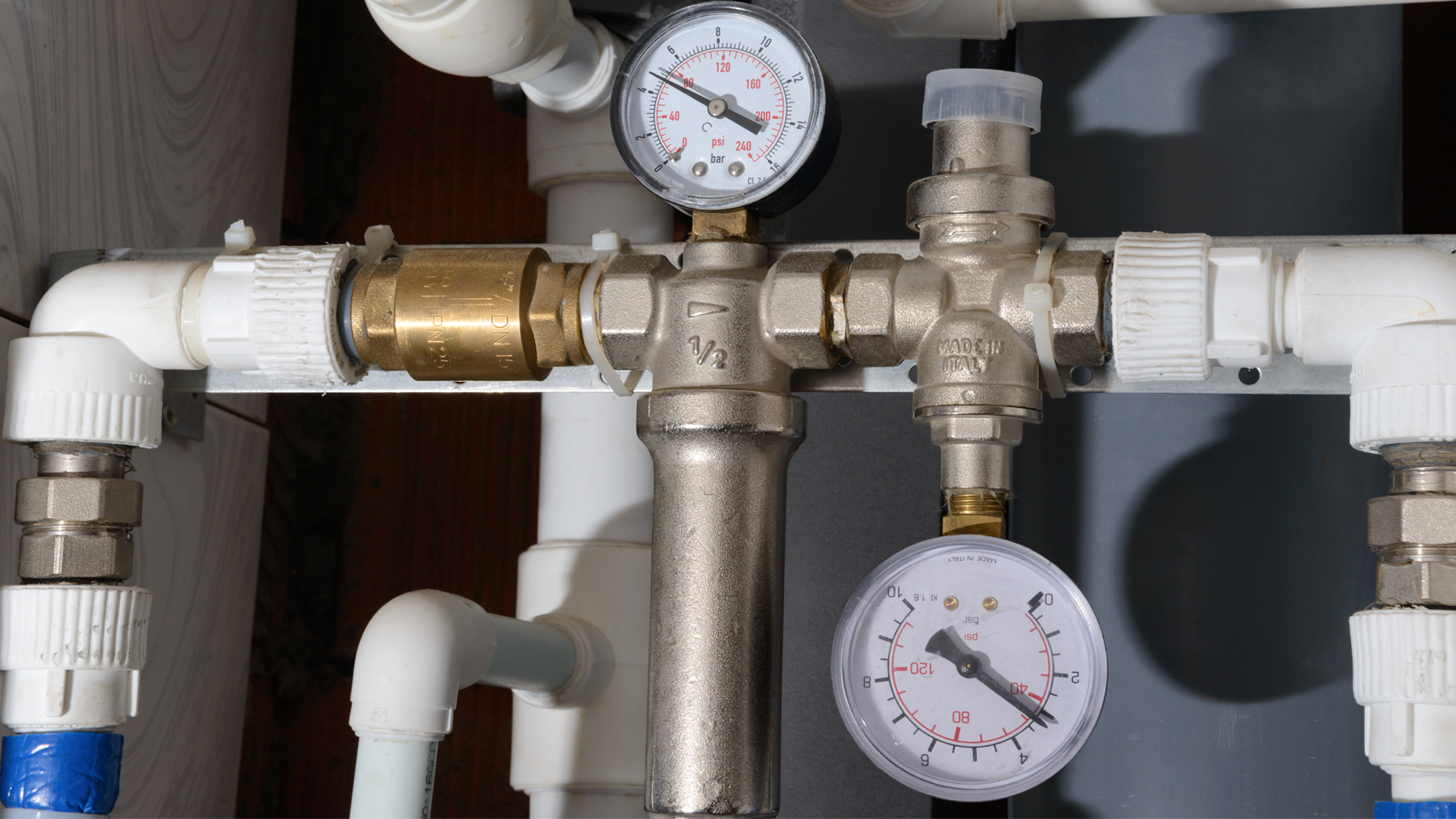

Isolation valves halt the flow of fluids or gases in their tracks, while regulation valves tweak flow and pressure. Safety relief valves keep the operation safe by letting off extra fluid, and non-return valves make sure nothing flows backwards.

Lastly, special purpose valves are the go-to for unique needs. When picking a valve, think about what you are working with- gas, steam, or liquid. The right match means better performance and a longer life for your valve. A good valve choice means efficiency and safety, ensuring your whole system sings harmoniously.

Also Read: Analyzing Types of Industrial Valves

Industries That Use Valves- An Overview

Valves are everywhere! They are crucial in many operations involving chemicals, fluids and gases. Let us spotlight a few key players:

- Energy generation: Valves manage steam and water for turbines and coolers.

- Water sector: Water treatment and delivery plants thrive on valves to keep the water supply consistent and safe.

- Oil and gas: Valves take charge of wellheads and pipes, even in extremely high pressure and temperature.

Knowing this, you will see how essential valves are when we zoom in on their role in energy creation.

Selecting the Right Valves- Tips for Industries

Looking for industrial valves? It might feel like a maze, but picking the right one is a game changer for safe and smooth operations. Here is how to make a smart pick

First, the valve material is a big deal. Check if it aligns well with what It is controlling.

Secondly, size is key. The valves should match your pipeline for the best flow and pressure.

Thirdly, pressure rating tells you the maximum pressure the valve can take.

Each valve design has its own perks, so consider what features you need. A trusted manufacturer means you are getting quality, and while cost is significant, remember to weigh it against quality. Keep these pointers in mind, and you will be set to find valves that will make your industry shine.

AlterValve is a valve supplier that offers a wide range of high-quality industrial valves and parts for various sectors such as power plants, oil and gas, petrochemicals, and more. It sources its products from qualified valve manufacturers and supplies in China, India, and Russia, and ensures that they meet strict quality and safety standards.

Aligning Valve Selection with Industry Excellence

Handling fluids and gases is serious business, and it demands gear precisely engineered for your system. Picking the right valve from reliable valve suppliers for complex industrial setups is not just a smart move. It is about keeping your system safe, efficient, and running for a long time.

With a solid grasp of valve types, uses, and what to look for, you will have your industry humming along with top-notch precision and safety.